KINAZO E1

WORLD’S FIRST 3D PRINTED

ENDURO E-BIKE

INTRODUCTION /

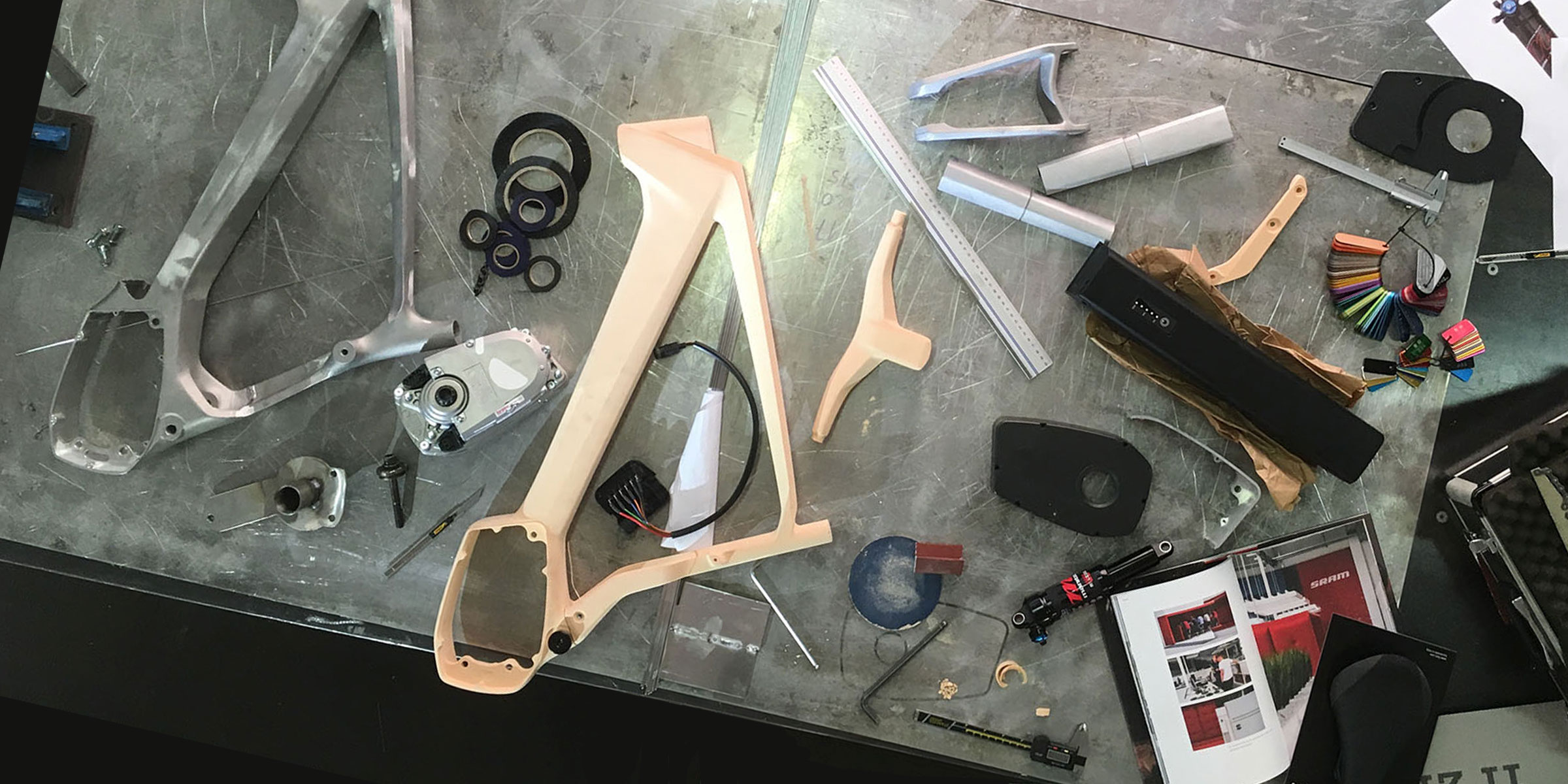

In the beginning there was an idea to build something out of this world – an e-bike, a bicycle with an integrated battery and engine anyone would fall in love with at first sight. Every figure, weight and style would be customized to the journey the customer wants to take. It would be unique, with the finishing touches and configuration to be made by the customers themselves. The idea became real with a 3D print of aluminium powder, rapidly evolving and enabling not only the manufacture of individual products, but also to print a design traditional methods could not have managed. Innovative 3D printing technology optimises the active weight, geometry and various technical parameters with significantly lower time and cost and no long manufacturing delays.

Today after years of hard work we finally present Kinazo E1 – the world’s first 3D printed enduro e-bike.

WHY IS E1 DIFFERENT /

Refined frame geometry with tuned centre of gravity allows dynamic and agressive riding in extreme terrain. Fully integrated battery supports sleek and eye-catching frame design. Intelligent electronic control system works through mobile app connected with GPS navigation. Unique frame is printed by progressive 3D technology of Additive Metal Manufacturing using Selective Laser Melting (SLM).

E1 was printed by Concept Laser X Line 2000R which is actually being the largest serial made metal melting machine. This 3D printer is based on Selective Laser Melting (SLM) which uses a precise, high-wattage laser to micro-weld powdered metals and alloys to form fully functional metal components. Thanks to the Concept Laser printer we were finally able to print an e-bike frame parts as single pieces instead of printing smaller fractions (our first prototype was welded from 11 pieces). 3D printed Kinazo E1 offers wide options of customization like geometry modified to body of rider, specific design, shape, reinforcement or even material microstructure.

FRAME DESIGN /

Development of E1 frame construction was based on the highest demands being put on enduro mountain bikes which must be able to handle balanced uphill climbing while staying reliable in steep and dangerous downhill sections at the same time. First tests of frame prototype revealed surprisingly good riding capabilities. For performance focused riders the quality of ride especially bike control and stability in terrain is essential. That’s why not only centre of gravity, but even more factors like overal bike weight feeling, frame stiffness etc. have to be considered in development process. Suspension system consists of 4 pivots which means no negative influence on rear triangle from brakes and drivetrain. E1 ranks among progressive frames with fine geometry and shorter chainstay length which makes it stable and easily maneuverable.

Patrik Paul and Slavomír Ozaník worked on the design with the KINAZO DESIGN team.

MOTOR TECHNICAL DATA /

Dimensions 213 x 150 x 128 mm

Weight 3,400g

Motor type mid-drive motor

Nominal voltage 36V

Rated continuous power 250W

Assistance Pedelec up to 25km/h

Assistance S-Pedelec up to 45 km/h

Pushing aid up to 6 km/h

Ingress protection rating IP56

INTEGRATED V7 BATTERY /

Capacity 14.0 Ah

Charging contact Binder plug

Discharge contact Blade contact

Connector box no

Lockable yes

Support rail integrated

Weight approx. 2,940 g

Color black